Award-winning White Dry Ink Delivers on Customer Demands and Profit Margins

Special effects aren’t just for Hollywood. Savvy customers now demand digital print enhancements for their printed communications, to make their messages stand out. The Xerox® Iridesse® Production Press and Xerox® iGen® 5 Press’ White Dry Ink delivers.

Benchmark White Ink Performance

Xerox developed White Dry Ink in response to customer demand to address a range of applications such as brochures, business cards, greeting cards, invitations, point-of-purchase signage and folding cartons. It represents our commitment to investing in new digital printing enhancements that enable new applications, add value to existing work and, for print providers, create competitive differentiation. Print providers who offer White Dry Ink to their customers can command premium pricing.

Industry Sits Up, Takes Notice, Bestows Accolades

Xerox White Dry Ink is gaining industry recognition as a top performer — it won a 2017 Must See ‘Ems Award as one of the most innovative new products at Print 17. (Xerox® Specialty Imaging Products also won a Must See ‘Em.)

Behind White Dry Ink’s early acclaim are brightness and opacity achievable in a single pass of white, while competitive digital presses can require four or more passes to achieve acceptable brightness and opacity.

Specialty Inks Are Available on Xerox Presses

At Print 17, we expanded the iGen 5’s fifth print station palette by introducing the new White Dry Ink option, joining Clear Dry Ink, the Orange, Green and Blue gamut extension colors and — in select markets — MICR.

Xerox is helping print providers achieve more productive and less expensive operations by delivering specialty inks through the fifth print stations on the Xerox® iGen® 5 Press and Xerox® Iridesse® Production Press.

More Ways White Dry Ink Benefits Print Providers

Further boosting productivity, a multi-pass feature on the iGen 5 enables two layers of white to be printed automatically over or under CMYK — and will provide sufficient coverage for the majority of applications. Additional layers of white can be manually printed for custom applications.

The Xerox approach also reduces printing costs because, where other digital press suppliers charge for each printed image (click), as well as for the ink, Xerox charges only for the ink. There are no click charges for printing from the iGen 5’s fifth print station for the Clear or White Dry Ink. Check out the Xerox Specialty Dry Inks page to learn more about White Dry Ink.

Contact Us

Find out how White Dry Ink can help your print applications stand out with striking effect.

Meet the Xerox® Iridesse® Production Press

Meet the Xerox® iGen® 5 Press

Related Articles

Solving Print's Pain Points

Explore the latest trends and solutions in print operations with Printweek’s special supplement, sponsored by Xerox. Gain insights into digital transformation, efficiency, and sustainability for your print business.

Unlocking Profits with Digital Embellishments

Get ready to dazzle your clients and boost your bottom line with this power training session from Xerox and Taktiful. Learn strategies to become more profitable marketing, pricing and selling Beyond CMYK applications.

Xerox Iridesse Virtual Designer Training

Add popular digital Beyond CMYK embellishments to your projects when using the Xerox Iridesse Press.

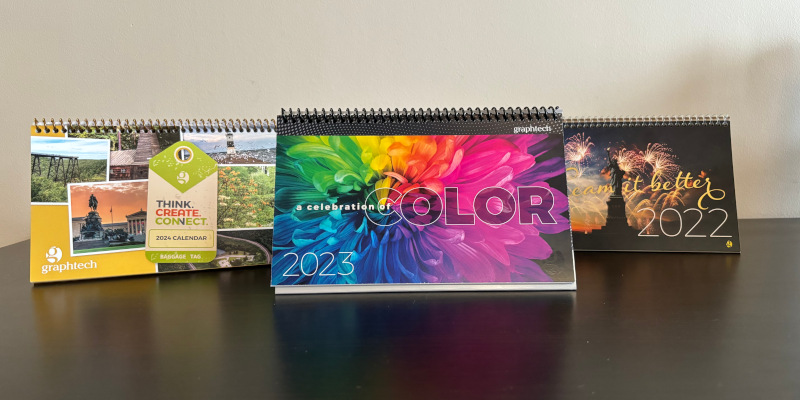

Rapid Press and Xerox: Building Success Together for over 30 Years

Discover how Rapid Press enhanced client satisfaction and productivity with the Xerox® Iridesse® Production Press and gold speciality toner, delivering high-quality, consistent prints that exceed expectations.

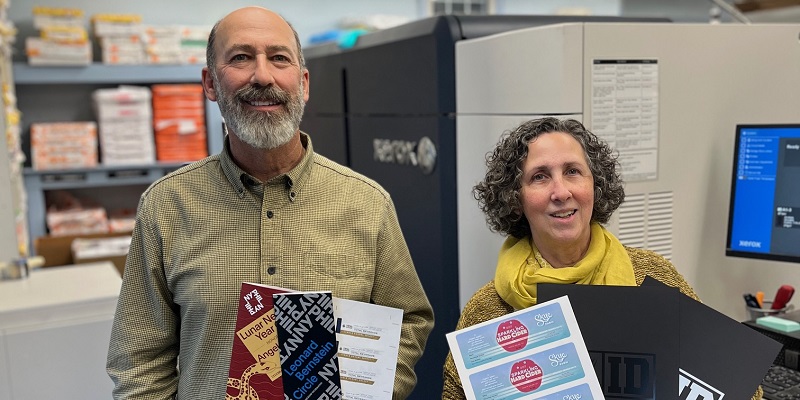

Xerox® Iridesse® Presses: Empowering Clients with On-Demand Printing

See how Xerox® Iridesse® Presses helped a client meet complex client needs with on-demand printing, exact quantities, and specialty embellishments, all while maintaining high standards.

UK printer delivers high-value projects while lowering environmental impact

Rapidity gains efficiency, versatility with Xerox® Iridesse® Presses