An Explosion of Colour: Frisco Independent School District Reconfigures for Growth with Inkjet

With 73 schools and 66,000 students, Frisco Independent School District (ISD) in Texas is one of the nation’s fastest growing public school systems.

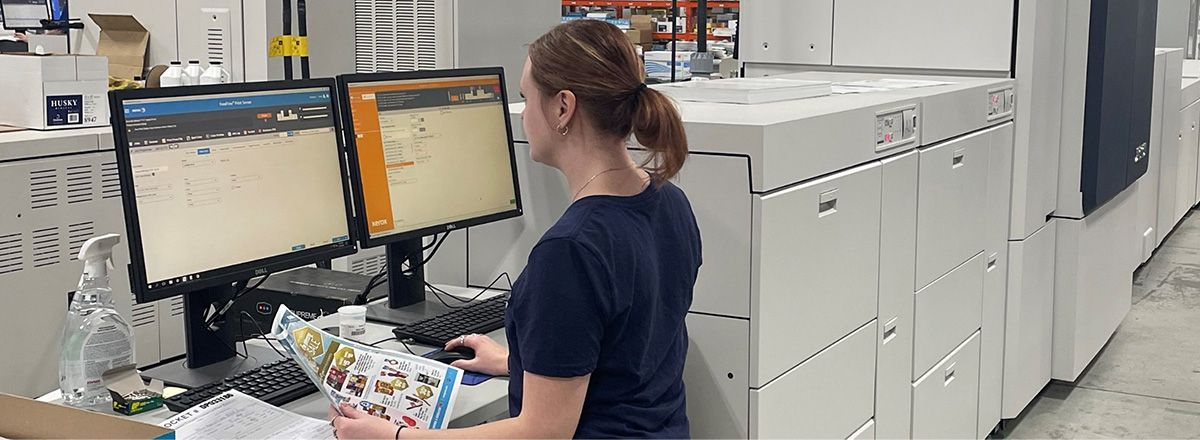

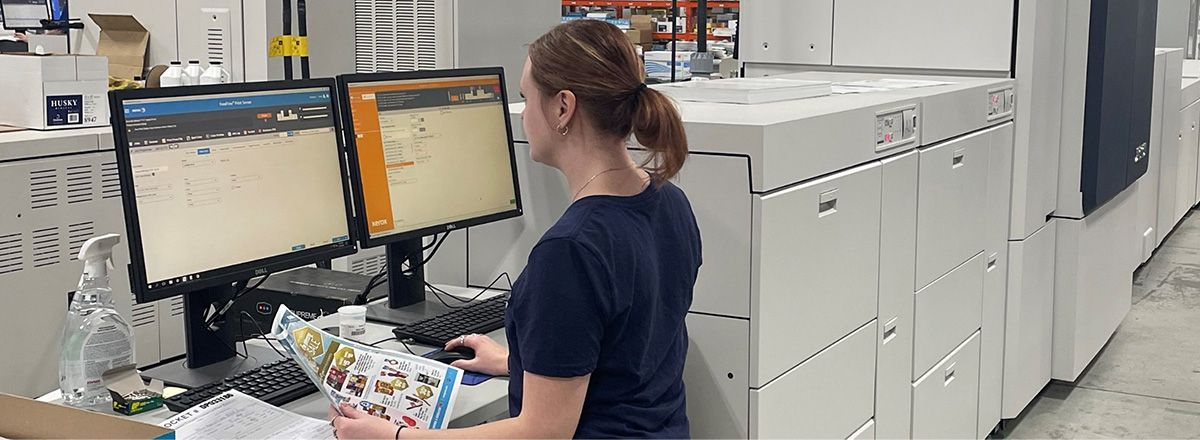

Serving the diverse print needs of this expanding educator, student, staff, and family community is the Frisco ISD Print Center. A long-time Xerox shop, this in-plant print operation comprises 13 Xerox Nuvera® 120 Presses, 2 Xerox® Iridesse® Production Presses, and a Xerox® Versant® 3100 Press in a tight footprint that—as recently as late 2020—pushed out more than 2,500 jobs a day, 10 million impressions each month.

With continual district expansion, however, the Print Center was getting concerned about their ability to take on any additional volume. There was no available physical space to squeeze more production equipment into their shop. They were “landlocked”—which was a big problem.

A Long, Long Fuse

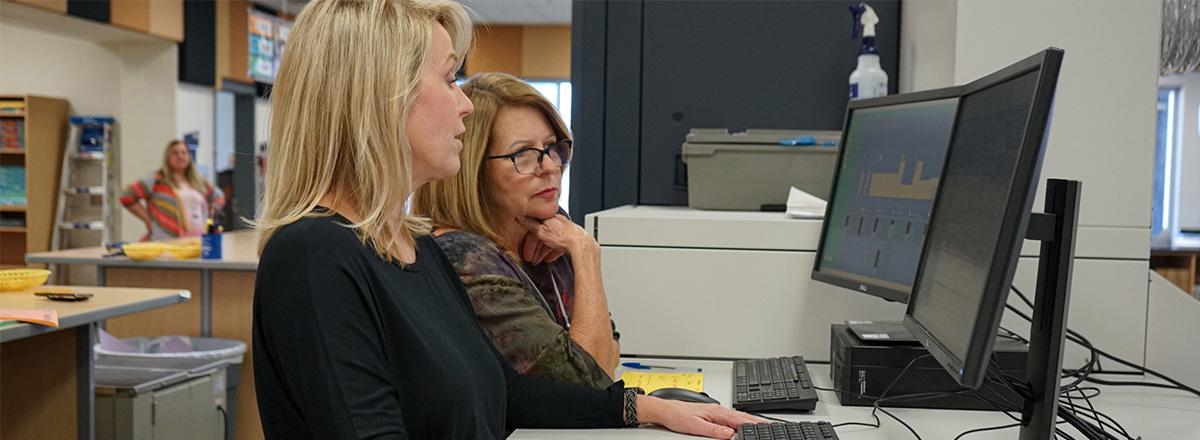

According to Sherri Broderick, Frisco’s Manager of Print, Mail and Sign Services, the team had long contemplated a move toward inkjet to help manage their growing volumes at lower per-page costs, but despite a general sense that it would be a good strategy, they had not acted. “We want to be cutting edge—and we are in many areas, including web-to-print,” she said. “But when it comes to actually making the jump to inkjet, we took our time making the right decision.”

Two things happened to crystalise what had up until then been an often discussed but never instituted strategy.

“We want to be cutting edge—and we are in many areas, including web-to-print,” she said. “But when it comes to actually making the jump to inkjet, we took our time making the right decision.”

A Burst of Colour

Suddenly, colour was everywhere. “There was a desire to improve the student experience—increase retention and raise test scores,” Broderick said. “Colour was exploding.”

Research has long shown that the use of colour in educational materials can improve attention span and recall—so naturally teachers and administrators wanted to use colour as much as possible to boost engagement. But the same Xerox® Iridesse® and Versant® Presses that allowed the Frisco ISD Print Center to produce stunning, premium-colour marketing materials, graduation programs, and other high-end applications, were cost-prohibitive for producing everyday colour for curricula-related output. They needed a more cost-effective option.

From Headwinds to Opportunity

Early in 2020, everything changed. With pandemic restrictions keeping students at home, monthly print volume declined drastically. Coupled with looming equipment lease renewals, there was a clear opportunity to re-evaluate equipment mix, footprint, and operational efficiency.

CHALLENGE: Affordable Colour with Room to Grow

“We had to look at something that was going to give us a higher speed, and capability to do the volume that was going to come into play five years from now,” Broderick said, without growing headcount—that meant more automation for fewer touches. Also topping their list of priorities was finding a way to offer lower-cost standard colour to educators and freeing up space in their packed production floor for better access and more finishing devices.

Frisco ISD “Must Have” Objectives

Cost Optimise

Reduce ink and toner costs; make standard colour more affordable for instructional materials.

Expand Capabilities

Free up Iridesse to produce more high-value applications and keep admin and marketing business in house.

Right-Size

Trim Nuvera fleet without sacrificing redundancy so they can meet seasonal demand.

Automate

Add efficiencies with more workflow automation and more inline finishing. Create a more touch-free process end to end.

The Frisco ISD team identified their must-have objectives, which included reducing the cost of standard colour output, ability to handle projected post-pandemic work volumes, and getting work in and out of the shop faster and more efficiently.

SOLUTION: A Better Together Approach

Frisco ISD engaged their trusted Xerox team for assistance—including extensive cost/savings analysis around making the jump to inkjet, as well as discussions around reliability, automation, and increased productivity.

The resulting plan embraced their current needs—and relevant existing equipment—while providing the flexibility to scale up in the future as needs change and the district continues to grow.

By adding two Xerox® Baltoro® Presses, Frisco ISD was able to reduce the cost of providing high-quality, standard colour curricula to their student body. And with an attractive per-page price for monochrome, the new Baltoro® Presses could also reliably support ongoing requests for mono/black and white jobs.

Presă Inkjet HF Xerox® Baltoro®

They also were able to:

Right-size their production footprint for capacity and redundancy, eliminating 10 of their 13 Xerox Nuvera® Presses and upgrading the remaining three.

Add new inline finishing devices to speed job completion and reduce the need for hand finishing.

Free up their Iridesse® Press for higher-value colour jobs—keeping more work in house and adding growth opportunity.

And by using Xerox® FreeFlow® Core workflow automation software to add vital information to job tickets, preflight and route jobs to the appropriate queue for finishing, they have added greater efficiencies and speed to their entire print operation while freeing up staff for other tasks.

BEFORE

13 - Xerox Nuvera® Presses

2 - Xerox® Iridesse® Production Presses

1 - Presă Xerox® Versant® 3100

AFTER

3 - Xerox Nuvera® Presses

2 - Xerox® Iridesse® Production Presses

2 - Xerox® Baltoro® HF Inkjet Presses

Xerox® FreeFlow® Core workflow automation

Smaller footprint

Lower colour cost

Faster mono

Integrated workflow

Dedicated high-value colour

Redundancy

Results

Flexible. Affordable. Future-Proof.

The successful transformation was achieved in a matter of months, thanks to careful planning and commitment on both the Frisco ISD and Xerox teams.

“It was really a whirlwind install,” Broderick said. “But Xerox brought its A-team, so everything went smoothly.”

100%

Increase in speed on mono jobs

200

More jobs through the shop every day by putting colour and mono on the same press

90%

Reduction in the Cost per Impression for colour

100%

Savings passed along to the district

Along with faster turnaround and more affordable colour and mono output, Frisco ISD has set a goal of keeping more jobs in house by utilising their Iridesse® and Versant® Presses to their fullest potential. “There’s a lot of potential there,” Broderick said. “People are on Zazzle.com or Pinterest, and they see things,” she said. They call and ask, “How can I get that?” She is pleased to let them know their team can help. “We now have the flexibility to give them some really diverse options.”

The increases in speed and volume—although projected and expected—surprised and delighted print shop workers—who initially were unable to keep up with sorting and bundling the faster output. “There was a lot of excitement,” Broderick said, around getting to know the new equipment and capabilities of the Baltoro® Press. “That was huge.”

4 Strategies for a More Flexible, Future-Proof Print Operation

Featured Technology

Presă Xerox® iGen® 5

Be ingenious.

Xerox® FreeFlow® Core

Automation and integration for your entire print workflow.

Articole Asemănătoare

How to Say ‘Yes’ to Anything: M&T Printing Group Thrives with Inkjet

Ontario-based print shop can take on any print job now they have added an inkjet digital press to their fleet.

4 Strategies for a more flexible, future-proof print operation

The switch from offset to digital is continuing. Position your print shop for the growth in diverse, short-run jobs.

The Inkjet Opportunity

This white paper looks at how production inkjet can transform your print operations, and considerations when comparing inkjet to offset and Xerographic technologies.

The Total Cost of Ownership of an Inkjet Press

Avoid hidden costs lurking below the surface.

Inkjet in Action

The Total Cost of Ownership of an Inkjet Press